Machining is the term generated by the word machine. Machine

is a type of instrument which is meant for the ease of human being. Machine reduces

the human efforts while implementing on a very hard work to do physically. Example

lifting a heavy material is impossible with the help of your hands, but whereas

it is much simple to do by help of a crane machine. Cranes are made to move very

high metal bodies from one place to another. We can have an example of a small

machine that is a screw driver which opens and tights a screw so easily that a

human hand would do it in no manner. This reduces the effort as well as the

time.

Machines do their job effectively as prototyping manufacturing. Doing this job of injection mold making by machine

is only known as Machining. Several countries are working on the process of machining

and generating new machine with the help of old machining. Bigger machines are

used to produce small machines which can be easily be used by humans.

Prototyping Manufacturing Cycle

Manufacturing process include a long cycle of full

completion of generated new product for use.

Product Development Cycle starts with:

1 Requirement Analysis

Firstly the requirements for the product

are analyzed which gives an idea about the major uses of the product to be

generated. A report is being generated

which includes the best results of the product to be generated.

Requirements

are to be made by customers which are going to use the product. Machine development

should target the best and optimized solution or the result to be given out by

the product to be generated.

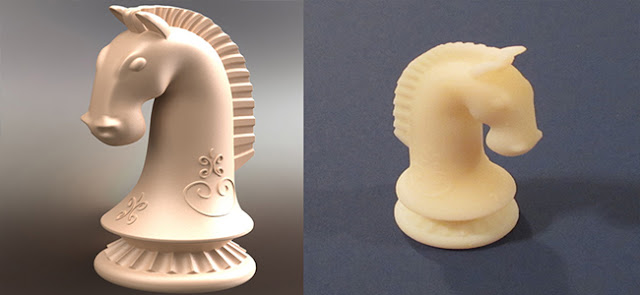

2 Designing

Designing part includes the architecture of die casting parts or may be the precision making parts or nay other product to be designed for the appearance of the product that how it will

look or to be handled by others for the better use and better result to be

received.

Design affects the working of the product and the result by it. Best

designed product gives the right place of holding and operating the machine

parts.

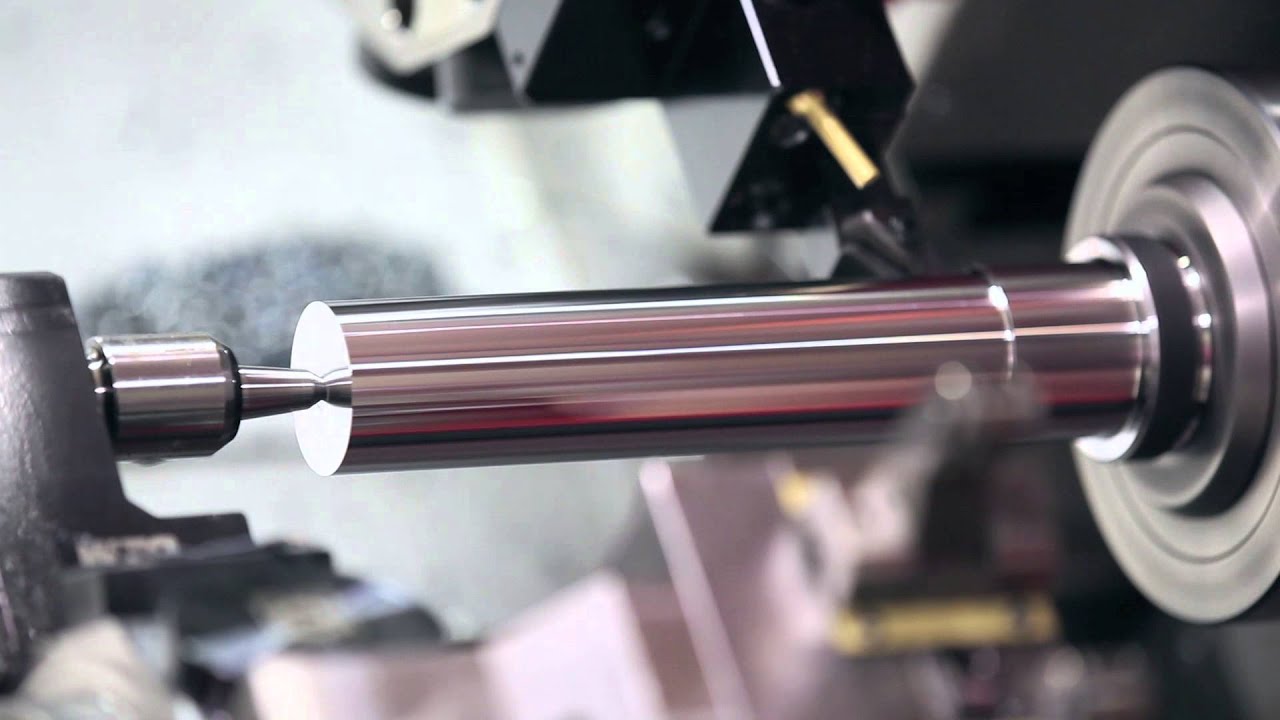

3 Machining

Now this includes the overall machining

process meaning the real facts behind manufacturing the product and finishing

it. Manufacturing of the product including all the processes are included are

in this stage.

The processes included are as follows:

a.

Die Casting Manufacturing

c.

Custom Injection Molding

And more processes are to be

followed to generate a product. These processes are included in converting raw

material into a usable product.

4 Testing

Testing comes after machining of the

product. Product generated is needed to be tested before delivering it to the

customer. All the possible tests are to be done, for several outcomes and

inputs.

5 Delivery

Delivery is the last part of cycle which includes

simply delivering the generated products to the customer as per the requirement

or bookings done.