There are varieties of job in our surroundings. Some jobs are very important and some are visible. But is that it? Are there no other types? To be honest we hardly look beyond these two categories when we talk about various jobs. Every job is Important for it works towards the development of self & society. It somehow gets included in the cycle of everyday activities. One such invisible job is Injection Molding Companies. Its very predictable to say that not many people known what it is. Its one of the toughest and time-taking job which needs greater knowledge and skills.

However, the process of injection mold manufacturing have become a less time-taking and nerve wrecking one after the regular utilization of advanced technology and machines. Injection molding is a process where every essentials you use in your day to day life (apart from foods) are given shape. From plastics to metals (iron, steel etc.), the product is molded and injected with polymers before giving them a final shape.

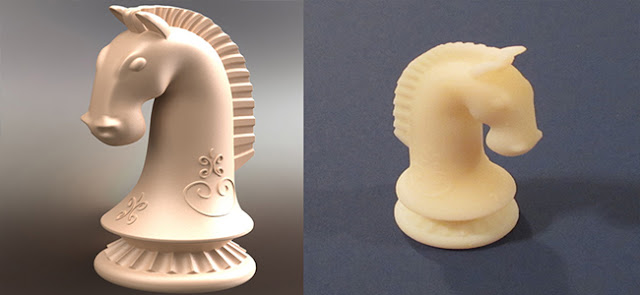

In the first stage the product to be created is designed with all the measurements and details by the collaborative effort of designing experts. Then the blueprint or the design are taken for sampling. Once approved the product manufacture begins in a full fledged manner. But in reality its not as easy as it sounds. The stage where sampling takes place is very crucial as its not always a 100 % error free procedure. Sometimes the samples might also come as a complete disaster. In sampling, the plan or the design of the product is implemented; every part of the product is molded and put together for the injection and final touch. The injection molding machine has components namely the injection unit, the mold and the clamping unit. The cache here is the machinery involved in injection molding. They are very expensive, sensitive and complex equipments. Which is why companies prefer outsourcing their product requirements to the injection mold companies and tooling factories than making those themselves.

The whole injection molding manufacturing process is taken care by highly efficient engineers who work in well equipped workshops. The end product brings more satisfaction when the company's engineers/ designers also collaborate with the factory employees. Few factories such as artetooling.com gives you such facilities where the company can put forward there demands and suggestions for a clear understanding of the product requirement. It is advisable to go through the workshop and the quality of products before taking the wise decision of trusting a factory for your services.